The Spring of Success

a unique independent

spring unit

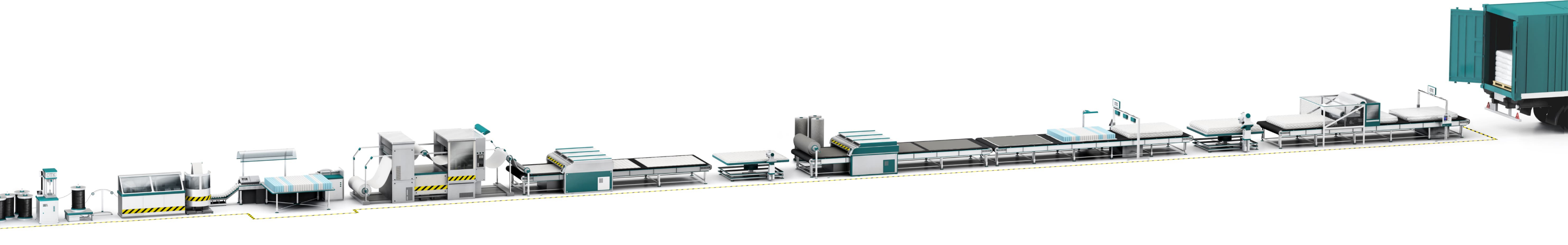

At Askona, we utilize a one-of-a-kind automated production line to manufacture our high-quality mattresses. Our production process relies on components and materials sourced from the world's top manufacturers.

We have our own in-house sleep testing laboratory, certified according to ISO 9001 standards. It was designed in collaboration with leading German and Swedish manufacturing companies.

Aligning with the European UCO system, Askona lab experts test and certify products based on their

operational characteristics.

Askona's production today consists of 10 factories, producing over 15,000 goods and featuring the

largest conveyor line in Europe.

Plus, Askona holds numerous patents for spring blocks and materials, as well as licenses for producing

leading global brands.

Every day, we produce:

Logistics

Askona Logistics Network is Europe's largest specialized furniture logistics network, comprising three transport hubs and 53 regional warehouses. It also serves as a service center for processing and tracking orders and providing customer reviews.

Every year, we execute over 987,000 deliveries to customers, with an OTIF (on-time-in-full) indicator of 98.2%.

New Technologies for a Better Mattress

Most of the equipment used in Askona production is unique. We have an integrated 3-conveyor production system, an automatic production management system, and planning and accounting tools for raw materials and finished products. Askona's specialists have developed a novel, non-standard assembly sequence for mattresses, which has significantly reduced production costs. We are able to pass these savings on to our customers by reducing the market price of our mattresses.

In our production process, we now utilize a new automatic glue line. This machine applies precise amounts of molten glue granules exactly where needed, ensuring a high-quality bond. Additionally, the new melt glue is odorless and completely harmless to our workers and the environment. This new technology has not only improved the quality of our products but also enhanced our work culture.

Stages of mattress manufacturing

shop of the Askona factory

Askona’s team has developed an optimized manufacturing process that has significantly reduced costs, allowing us to pass the savings on to customers.

Advanced Materials and Techniques

We continuously update our collections of mattresses, beds, and accessories. Our new collections are based on the most modern scientific developments, which our specialists rely on. Our goal is to make your sleep healthy and comfortable. All materials we use in our mattresses and sleep accessories are absolutely safe and comply with international standards, including fire safety.

In our mattresses and sleep accessories, we use a combination of time-tested materials like coconut board or sisal, as well as the latest innovations like viscolatex and gel. Our "deep stitch" technology allows us to create mattresses that are more comfortable than ever before.

Recently, Askona has successfully introduced the production of roll-up spring mattresses, which simplifies transportation and logistics.

Quality Control

At Askona, we pride ourselves on consistently delivering high-quality mattresses. Every material and component used in our mattresses meets the highest standards for anatomical products. Before each new model or series is released, it undergoes rigorous testing to ensure its quality.

To maintain the highest levels of quality and stability, we have implemented a multi-stage quality control process for both raw materials and finished products through our in-house quality control laboratory.

Materials for Making Mattresses

Askona uses only modern, high-quality, and environmentally friendly materials from leading global manufacturers in the production of mattresses. All of these materials meet international quality standards for safety.

This spring contains several levels of firmness, offering universal comfort for almost any person. Unlike other springs, which are initially either firm or soft, the HourGlass spring can provide different sensations.

The five- or seven-zone unit of independent springs has an exceptional anatomical effect, providing exceptional support and comfort.

The high lignin content of coconut fiber makes it highly elastic and resistant to decay. Its excellent performance qualities and long service life have made it a popular choice for mattresses.

Latex is often used in premium mattresses, providing a high anatomical effect. The latex filling of the mattress perfectly conforms to the body’s contours, ensuring ideal comfort.

Memory foam ensures even load distribution, preventing blood circulation disruptions and providing unique anatomical properties.

It is a natural fiber derived from the fresh leaves of the Agave plant. It is moisture-resistant, hygienic, and can withstand heavy loads without compromising its shape or structure.